|

|

- Search

| J. People Plants Environ > Volume 25(6); 2022 > Article |

|

ABSTRACT

Background and objective: For a successful application of agrivoltaic (AV) system, decrease in crop productivity must be minimized while achieving power generation. In this study, changes in microenvironments, crop growth and quality under the AV panels were investigated for kimchi cabbage.

Methods: On September 1, 2021, kimchi cabbage (Brassica rapa ssp. pekinensis) ‘Bulam No. 3’ was planted in the soil under the AV panels and in an open field for the control, and grown using a conventional method. Growth characteristics and internal components after 16 weeks were analyzed.

Results: There was no difference in air temperature and relative humidity, however daily light integral (DLI) and soil temperature under the AV panels were lower than the control. Under the AV panels, plant width was lesser and plant height and head height were greater than the control. Head shape index and leaf number of the AV panel plot were greater than in the control. Trimming loss rate was lower but chlorophyll content was higher in the AV panel plot. Head hardness was lower in the AV panel plot, while head fresh weight was greater but head dry weight was smaller in the AV panel plot: therefore, moisture content was greater than the control. Marketable crop yield and heading rate was higher in the AV panel plot.

Conclusion: The environmental changes caused by AV panels including the DLI and soil temperature induced a larger fresh weight, higher heading and trimming loss rates because a relatively good environment was created in the early crop stage which was the period of high temperature and DLI. However, the lower DLI of the latter period had a rather negative effect, resulting in an elongated shape, smaller dry weight, and shorter shelf life.

Methods: On September 1, 2021, kimchi cabbage (Brassica rapa ssp. pekinensis) ‘Bulam No. 3’ was planted in the soil under the AV panels and in an open field for the control, and grown using a conventional method. Growth characteristics and internal components after 16 weeks were analyzed.

Results: There was no difference in air temperature and relative humidity, however daily light integral (DLI) and soil temperature under the AV panels were lower than the control. Under the AV panels, plant width was lesser and plant height and head height were greater than the control. Head shape index and leaf number of the AV panel plot were greater than in the control. Trimming loss rate was lower but chlorophyll content was higher in the AV panel plot. Head hardness was lower in the AV panel plot, while head fresh weight was greater but head dry weight was smaller in the AV panel plot: therefore, moisture content was greater than the control. Marketable crop yield and heading rate was higher in the AV panel plot.

Conclusion: The environmental changes caused by AV panels including the DLI and soil temperature induced a larger fresh weight, higher heading and trimming loss rates because a relatively good environment was created in the early crop stage which was the period of high temperature and DLI. However, the lower DLI of the latter period had a rather negative effect, resulting in an elongated shape, smaller dry weight, and shorter shelf life.

Agriphotovoltaic (or agrivoltaic; AV) systems, in which solar panels for AV are installed at regular intervals on the upper part of the farmland while crops are grown in the lower part under them, enable agriculture and photovoltaic (PV) power generation at the same time and in the same space (Jung, 2020). Currently, research and development on various demonstrations and applications for the system is actively underway both domestically in South Korea and abroad, including in the United States, France, Japan, and China. Such R&D are mainly conducted through government support in facilities (e.g., greenhouses and mushroom farms), as well as in agricultural lands (e.g., rice fields, fields, and orchards) (Ahn et al., 2022; Jung, 2020; Schindele et al., 2020; Trommsdorff et al., 2021; Vitisphere, 2020; Vollprecht et al., 2021).

As the lower part of AV systems a re subject to reduced light intensity with shading (Cossu et al., 2020), currently, attempts are being made in South Korea to cultivate sunny crops in addition to shade crops in PV greenhouses. Of such attempts, rice yield under the AV system in Goseong-gun, Gyeongsangnam-do was evaluated to decrease slightly to 85.9% compared to the control group (Seo, 2019). Although AV systems can increase profitability by at least 5 times compared to simple crop cultivation through efficient land use without farmland reduction, a decrease in light intensity may be directly linked to a decrease in crop yield and quality (Cossu et al., 2020; Loik et al., 2017); under existing AV systems, it was reported that the yield reduction rate reached 10 to 20% depending on the area ratio of crops and AV panels (Jung, 2020; Moon and Ku, 2022; Nagashima, 2018; Nam, 2018).

To maintain agricultural productivity as much as possible in AV systems, technologies to utilize the generated power are also required. Examples include the development of production technology that minimizes the yield reduction rate per unit area using supplemental LED light, automatic irrigation, and so on. Since solar radiation that exceeds the light saturation point may cause the problem of reduced photosynthetic efficiency (Falster and Westoby, 2003; Je et al., 2006) or withering crops depending on the crop, for crops that are susceptible to damage during the high temperature season, shading or temperature reduction by AV panels may have a positive effect (Lee et al., 2015; Oh et al., 2014).

Kimchi cabbage (Brassica rapa ssp. pekinensis), a biennial plant of the Cruciferae family, is a vegetable that is widely produced and consumed as the main ingredient of kimchi, a staple food in Korea. Recently, facility cultivation of the vegetable has been attempted. Kimchi cabbage, with 95% of production grown in open fields, is one of the typical field crops and is greatly affected by external weather conditions. When the growth temperature of kimchi cabbage, a psychrophilic vegetable, is higher than the optimal growth temperature, cell damage and decreased growth occur, resulting in both production and quality deterioration (Lee et al., 2009; Lee et al., 2011; Lee et al., 2012; Oh et al., 2014); the vegetable cultivated in summer is mainly produced in high-altitude areas as the high temperature and humidity environment in general farmland raises the risk of physiological disorders or pests. For this reason, damages caused by extreme weather events including torrential rains or abnormally high temperatures have a great impact on the price of the cabbage in autumn (Hwang et al., 2003). Therefore, AV systems are expected to reduce the damage attributable to excessively high light intensity and high ground temperature by blocking those during the high-temperature period (Cossu et al., 2020; Jung, 2020), which will have a positive effect on the vegetable. This study aimed to determine the effect of the environmental changes caused by AV system installation on the growth and quality of autumn kimchi cabbage, one of major open-field vegetables in Korea.

An AV system designed with a shading rate of 33% was installed as a fixed type with a panel angle of 30° facing due south in the Yeungnam University AV Experimental Center (35°81′81″ N, 128°76′47″ E) on November 6, 2019 (Fig. 1). AV panels were installed on 1,089 m2 (33 m × 33 m; AV panel plot) of the total farmland of 1,551 m2 (33 m × 47 m), and the remaining 462 m2 (33 m × 14 m) was left without AV panels for open-field cultivation (control plot).

Kimchi cabbage (Brassica rapa ssp. pekinensis) “Bulam No. 3” was selected as the experimental material, and its seedlings one month after sowing were planted on September 1, 2021. They were planted under the AV panels and in the open field covered with plastic film (control plot), respectively, and managed using conventional practices (RDA, 2021; Fig. 2).

At 16 weeks after planting, 10 specimens harvested from 4 cultivation points for each plot were compared in terms of growth, quality and storage characteristics according to the standard of analysis and survey for agricultural science and technology (RDA, 2012; hereinafter referred to as the Standard). The terms used hereinafter are defined as follows: the “ plant” for intact specimens immediately after being harvested with the roots cut off; “trimming” for the operation of removing the outer leaves damaged by drying or decay; and the “head” for the inner part remaining after selection (Lee et al., 2016; Kim et al., 2018). The trimming loss rate (%) was calculated as follows: [(plant weight-head weight)/plant weight] × 100.

As growth characteristics, plant height (PHT), plant width (PWD), head height (HHT), head width (HWD), leaf length (LL), leaf width (LWD), number of leaves, trimmed number (TN), leaf color (LC), stem weight (SWT), head weight (HWT), and hardness (HD) were measured according to the Standard (RDA, 2012). PHT and PWD were measured as the longest length and width of the plant, and HHT and HWD were also measured in the same way for the head after trimming. LL and LWD were measured as the length and width of the largest leaf, and LN was calculated as the number of leaves that were 1 cm or larger. The cold damage rate (%) was calculated as follows by checking the number of plants affected by cold damage including yellowing or brown water-soaked areas on the outer leaves immediately before harvest: [(Total number of plantings - Population affected by cold damage)/Total number of plantings] × 100.

SWT and HWT were measured as fresh and dry weight before and after trimming; fresh weight was measured before and after trimming, while dry weight was measured only after trimming. Dry weight was measured after drying specimens for 5 days in a dry oven (DS-80MP-1, Dasol Scientific Co., Ltd., Hwaseong, Korea) set at 80°C. LC was measured with a chlorophyll meter (SPAD-502Plus, Konica Minolta, Inc., Tokyo, Japan) on the mesophyll of the outermost leaf after trimming each specimen. The trimming loss rate (%) was calculated by comparing the reduced fresh weight after trimming to the fresh weight before trimming. HD was measured with a fruit hardness tester (FHM-5, Takemura Electric Ltd., Tokyo, Japan) on the mesophyll of the outermost leaf after trimming. The plant shape index (PSI), head shape index (HSI), and leaf shape index (LSI) were obtained by dividing PHT, HHT, and LL by PWD, HWD, and LWD, respectively. Moisture content (%) was calculated as [(fresh weight - dry weight)/fresh weight] × 1 00.

For an analysis of storage characteristics, after harvesting, 40 specimens for each plot were wrapped in newspaper without trimming, and then 5 specimens each were put into a zipper bag. While storing them in a low-temperature warehouse (RH 80 ± 5%, 1 ± 1°C), 10 specimens were taken out every 4 weeks, and the HWT, HD, and weight after trimming were measured.

A data logger (WatchDog 1650 Micro Station, Spectrum Technologies, IL, USA) was installed in the center of the control plot (i.e., open field covered only with plastic film) and AV panel plot, respectively; temperature and relative humidity were measured with built-in sensors. Then, by connecting a light sensor (#3668l Quantum light sensor, Spectrum Technologies, IL, USA) and a soil moisture/EC/temperature sensor (Spectrum SMEC 300, Spectrum Technologies, IL, USA) to this data logger, the photosynthetic photon flux density (PPFD) and soil temperature of each plot were also measured. Data for each environmental factor were collected at 10-minute intervals during the kimchi cabbage cultivation period. Of the collected environmental data, temperature, relative humidity, and soil temperature were calculated as daily averages, and PPFD was added up daily to obtain the daily light integral (DLI).

The crop characteristics were collected for a total of 40 specimens by harvesting 10 specimens each from 4 cultivation points (repetition) for each plot. The collected data were analyzed through F-test and T-test using SAS ver.9.4 (SAS Institute, Cary, NC, USA) at a significance level of 95% for the significant difference between the means of the two plots.

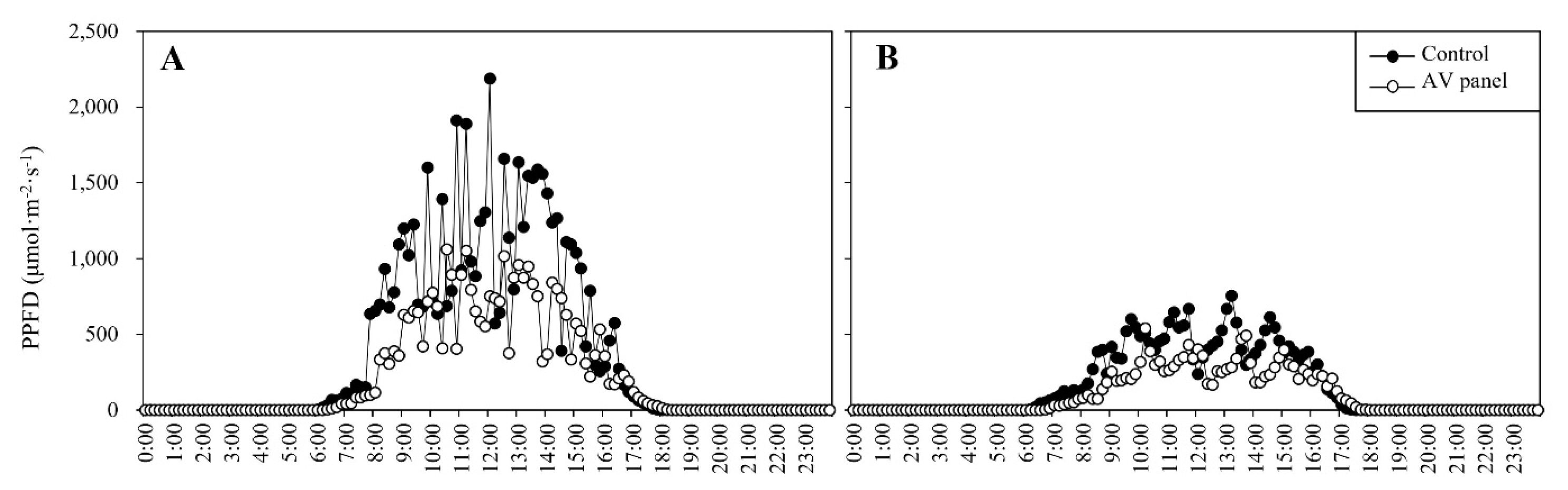

Since the AV panels block light, the plants in the AV panel plot receive less light than those in the control plot. In this study, the DLI of the AV panel plot was also lower, at about 51.3% of the control plot throughout the entire cultivation period (Fig. 3A). The difference in DLI between the two plots was greater on sunny days than on cloudy days, which can be seen from the variations in PPFD for one day (Fig. 4). This decrease in light intensity affects plant photosynthesis by changing leaf temperature and light interception (Moon et al., 2014).

There was almost no difference in temperature and relative humidity between the control and AV panel plots (Figs. 3B and 3D), which seems be attributable to the circulation of air, as the two plots were immediately adjacent. In addition, the body temperature of plants exposed to light is different from that measured without exposure to direct sunlight within an instrument shelter, so during the period of high light intensity, the actual body temperature is higher even if the atmospheric temperature is the same, which may have affected photosynthesis, transpiration, and leaf dryness (Faust and Heins, 1997; Graper and Healy, 1991; Oh et al., 2010).

The mean soil temperature of the AV panel plot was found to be 17.5% lower than that of the control plot (Fig. 3C). This seems to be caused by a decrease in the intensity of light reaching the soil (Oh et al., 2010). Since soil temperature affects not only evaporation from the soil surface but also various root metabolisms in the rhizosphere of plants (Luo et al., 2020) and the yield of kimchi cabbage (Yun et al., 2012), it is considered that the difference in soil temperature that occurred in this study may have affected the growth.

As for the growth characteristics of the whole plant, the PWD and HHT of the AV panel plot were 12.45% smaller than that of the control plot and 9.45% larger, respectively, resulting in a higher PSI of the AV panel (Table 1). For leaf growth characteristics, the LWD of the AV panel plot was 5.79% larger than that of the control plot, so the LSI was 6.39% lower (that is, the shape in which the width was longer than the height), but the chlorophyll content (SPAD) of the AV panel plot was 17.97% higher (Table 2). For morphological characteristics, compared to the control plot, the AV panel plot had a more elongated shape in terms of PSI and HIS (Fig. 5), and a higher chlorophyll content. Overall, it appears that the light blocking by the panels allowed the plants to have been slightly elongated, while having an increased chlorophyll content.

There was no statistical difference in plant fresh weight before trimming, but head fresh weight of the AV panel plot after trimming was 21.45% greater than that of the control plot (Table 3). That is, it can be seen that fewer outer leaves are discarded during trimming in the AV panel plot. The dry weight of the control plot was 22.02% higher, so the moisture content of the AV panel plot was 2.4% higher (Table 3). Consequently, since there is no statistically significant difference between the AV panel and control plots in the head fresh weight corresponding to the crop yield immediately after harvest, it can be seen that there is no difference in the yield.

As for other quality characteristics, the LN and trimming loss rate of the AV panel plot was 6.87% higher than the control plot, and 29.79% lower, respectively. The heading rate and cold damage of the AV panel plot was 197.72% higher than the control plot, and 15.04% lower, respectively (Table 4). In this study, cold damage occurred to the outer leaves due to a situation where the temperature dropped below zero just before harvest, but the damage rate was rather low for the AV panel plot (Table 4). Jung (2020) found that AV panels prevent cold damage by partially blocking snowfall, melting snow quickly, and blocking cold wind to some extent. Similarly, in this study, it seems that the cold damage was reduced and the quantity maintained as the cold wind was blocked by the AV panels to some extent.

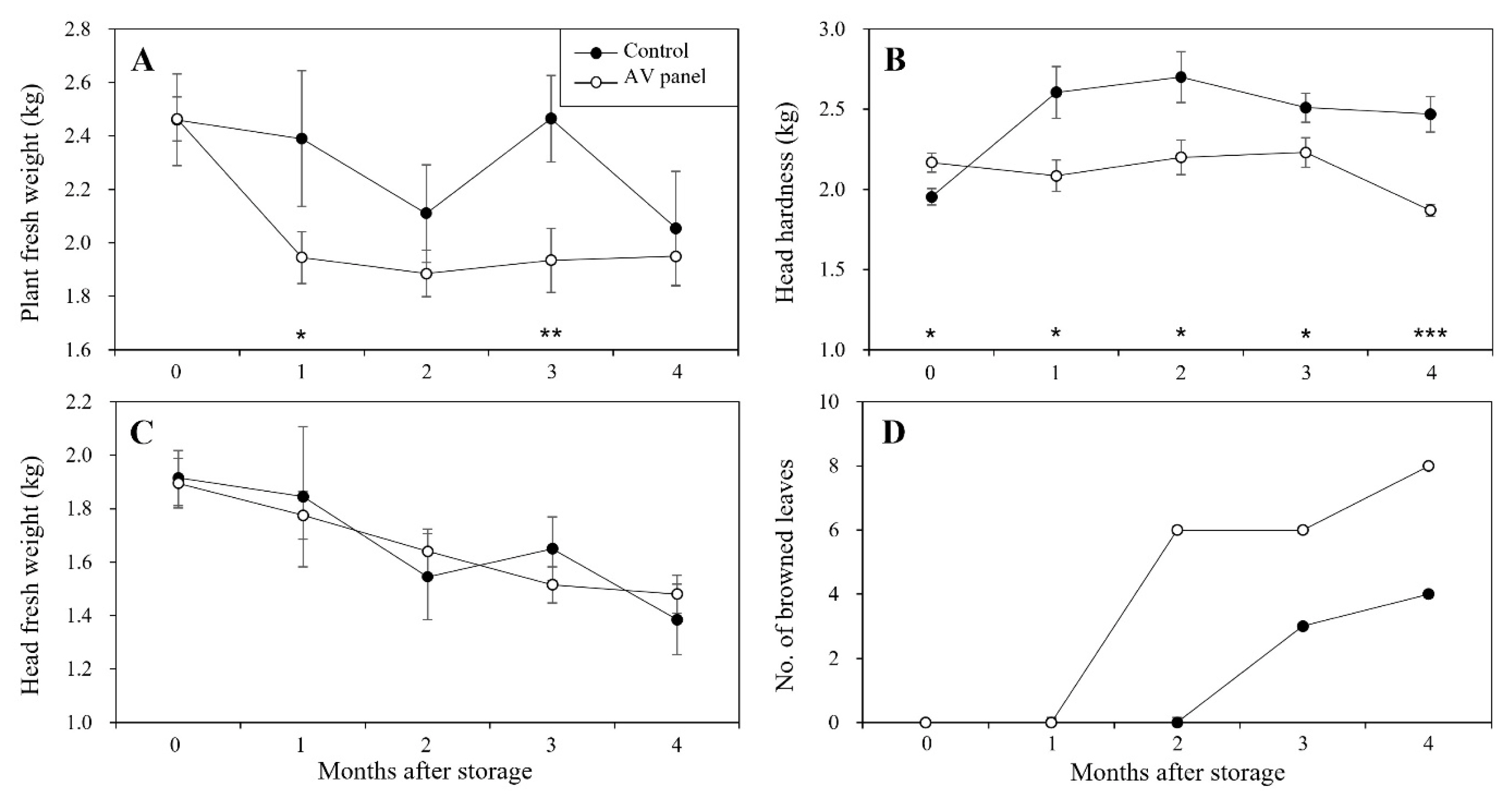

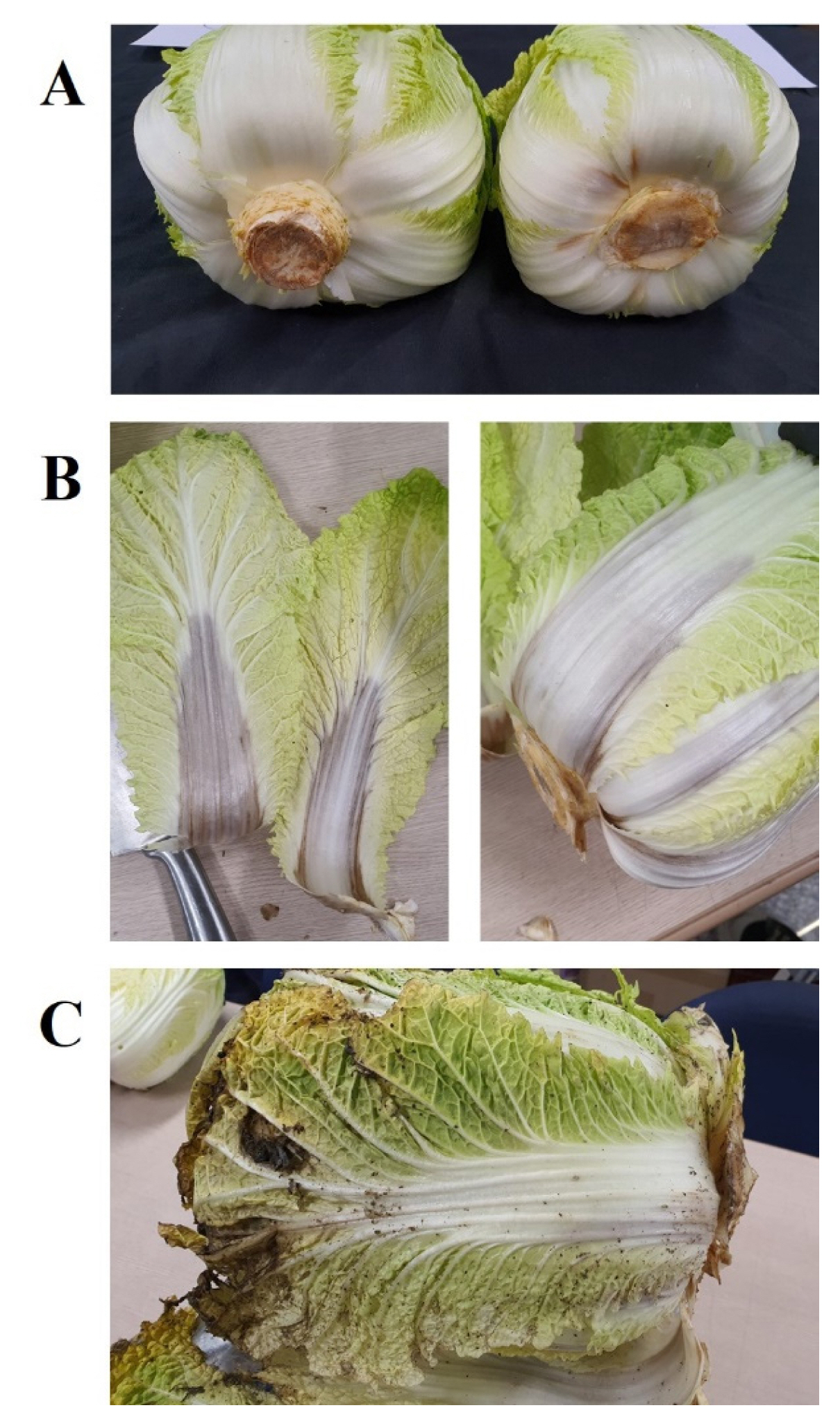

After trimming dead lower leaves with no commercial value generated during the storage process, the fresh weights of the control and AV panel plots were measured and found to be similar. However, both the fresh weight and hardness before trimming were consistently higher in the control plot (Fig. 6). At the 2nd month of storage, 6 specimens with browning at the bottom were found for the AV panel plot (Fig. 7A), and at the 3rd month, 3 with browning for the control plot (Fig. 7B), but the quantity was smaller than that of the AV panel plot, where an additional 6 were found. At the 4th month, the outer leaves began to rot (Fig. 7C), which also occurred less in the control plot, with 4 specimens for the control plot and 8 for the AV panel, respectively. Moisture content affects the storability of kimchi cabbage, especially autumn kimchi cabbage, which is sometimes stored after harvesting and drying. (RDA, 2015). In this study, the faster browning that occurred for the AV panel plot seems to be attributable to it having higher moisture content than the control.

This study aimed to determine the effect of AV panels on the microclimate and crop characteristics of kimchi cabbage by cultivating it under AV panels and on the open field (control plot) for the technical application of an agriphotovoltaic (AV) system. Based on the environmental data of the two plots, there was no difference in temperature and humidity, but the DLI of the AV panel plot was lower than that of the control, at only 51.3% that of the control plot, and the mean soil temperature was also 17.5% lower. For the AV panel plot, the PWD and HHT were 12.45% smaller than the control and 9.45% larger, respectively, so the PSI was larger and the number of leaves was 6.87% higher. The trimming loss rate and chlorophyll content was 29.79% lower than that of the control plot, and 17.97% higher, respectively. Compared to the control plot, the hardness, dry weight, and moisture content were 24.00% lower, 22.02% higher, and 2.40% higher, respectively. Both product rate (75.00% and 65.20% respectively) and heading rate (53.00% and 21.90%, respectively) of the AV panel plot were significantly higher than those of the control.

Based on the results of this study, it was found that the installation of AV panels in 30% of the cultivation area when cultivating autumn kimchi cabbage may reduce the intensity of light received by the soil and plants, thereby changing the soil temperature, as well as the microclimate (Cossu et al., 2020). In addition, it seems that these changes created a relatively better environment for crops and workers in the early planting period, which is a high temperature period, compared to the control plot (Son et al., 2018). However, during the period when the intensity of natural light decreases after rooting, it appears that the amount of light reaching the plant was reduced by the AV panels, which had a somewhat negative effect on the growth (Choi et al., 2021). As such, there was no statistically significant difference between the two (treatment) plots in terms of crop yield (head fresh weight) after harvesting and trimming, as the PV panels had contrasting effects on the plots over time from the start of cultivation.

Fig. 2

Kimchi cabbage ‘Bulam No. 3’ plants growing in the open field (control, A) and under the agrivoltaic (AV) panels (B).

Fig. 3

Changes in microclimate during growing period of Kimchi cabbage in the open field (control) and agrivoltaic (AV) panel. (A) Daily light integral (DLI), (B) daily mean air temperature, (C) daily mean soil temperature, and (D) daily mean relative humidity (RH).

Fig. 5

Heads of Kimchi cabbages grown in the open field (control, A) and under agrivoltaic (AV) panels (B).

Fig. 6

Changes in crop characteristics during low temperature storage of Kimchi cabbage grown in the open field (control) and agrivoltaic (AV) panel. (A) Plant fresh weight, (B) head hardiness, (C) head fresh weight, and (D) number of browning leaves. Vertical bars represent standard errors (n = 10). *,**,***Significant at p < .05, .01, or .001, respectively.

Fig. 7

The symptoms of leaf browning shown only in AV panel (right side) at 2 months (A), leaf browning shown in both section at 3 months (B) and leaf rotting at 4 months (C) after low temperature storage of Kimchi cabbage ‘Bulam No. 3’.

Table 1

Plant shape of kimchi cabbage ‘Bulam No. 3’ grown in the open field (control plot) and under the agrivoltaic (AV) panels

| Treatment | Plant height (A, cm) | Plant width (B, cm) | Plant shape index (A/B) | Head height (C, cm) | Head width (D, cm) | Head shape index (C/D) |

|---|---|---|---|---|---|---|

| Control | 34.15 | 33.68 | 1.04 | 27.47 | 20.04 | 1.40 |

| AV panel | 33.93 | 29.49 | 1.17 | 30.07 | 20.15 | 1.50 |

|

|

||||||

| Significance | NS | *** | ** | *** | NS | NS |

Table 2

Leaf shape of kimchi cabbage ‘Bulam No. 3’ grown in the open field (control plot) and under the agrivoltaic (AV) panels

| Treatment | Leaf length (A, cm) | Leaf width (B, cm) | Leaf shape index (A/B) | Chlorophyll content (SPAD) |

|---|---|---|---|---|

| Control | 35.29 | 21.32 | 1.67 | 31.68 |

| AV panel | 35.15 | 22.55 | 1.57 | 37.37 |

|

|

||||

| Significance | NS | * | ** | *** |

Table 3

Crop yield of kimchi cabbage ‘Bulam No. 3’ grown in the open field (control plot) and under the agrivoltaic (AV) panels

| Treatment | Plant fresh weight (kg) | Head fresh weight (kg) | Head dry weight (kg) | Moisture content of head (%) |

|---|---|---|---|---|

| Control | 2.95 | 1.60 | 0.124 | 92.1 |

| AV panel | 2.86 | 1.95 | 0.110 | 94.3 |

|

|

||||

| Significance | NS | ** | * | ** |

Table 4

Crop quality and injury of kimchi cabbage ‘Bulam No. 3’ grown in the open field (control plot) and under the agrivoltaic (AV) panels

| Treatment | No. of leaves | Trimming loss (%) | Hardness (kg) | Heading rate (%) | Cold damage (%) |

|---|---|---|---|---|---|

| Control | 78.65 | 24.73 | 2.62 | 21.9 | 92.4 |

| AV panel | 84.05 | 17.37 | 1.99 | 65.2 | 78.5 |

|

|

|||||

| Significance | ** | *** | *** | - | - |

References

Ahn, SY, DB Lee, HI Lee, ZL Myint, SY Min, BM Kim, W Oh, JH Jung, HK Yun. 2022. Grapevine growth and berry development under the agrivoltaic solar panels in the vineyards. Journal of Bio-Environment Control. 31(4):356-365. https://doi.org/10.12791/KSBEC.2022.31.4.356

Choi, SH, SH Kim, GL Choi, HJ Jeong, MY Lim, DY Kim, SY Lee. 2021. Growth and quality of the strawberry (Fragaria annanassa Dutch cvs. ‘Sulhyang’) as affected by complex nutrient solution supplying control system using integrated solar irradiance and substrate moisture contents in hydroponics. Journal of Bio-Environment Control. 30(4):367-376. https://doi.org/10.12791/KSBEC.2021.30.4.367

Cossu, M, A Yano, S Solinas, PA Deligios, MT Tiloca, A Cossu, L Ledda. 2020. Agricultural sustainability estimation of the European photovoltaic greenhouses. European Journal of Agronomy. 118:126074.https://doi.org/10.1016/j.eja.2020.126074

Falster, DS, M Westoby. 2003. Leaf size and angle vary widely across species: What consequences for light interception? New Phytologist. 158(3):509-525. https://doi.org/10.1046/j.1469-8137.2003.00765.x

Faust, JE, RD Heins. 1997. Quantifying the influence of high-pressure sodium lighting on shoot-tip temperature. Acta Horticulturae. 418:85-91.

Graper, DF, W Healy. 1991. High pressure sodium irradiation and infrared radiation accelerate Petunia seedling growth. Journal of American Society for Horticultural Science. 116:435-438.

Jung, JH 2020. Current status and prospects of agrivoltaic system. Bulletin of the Korea Photovoltaic Society. 6(2):25-33.

Kim, MN, HP Seok, CW Park, SY Choi, DS Choi, JS Kim, YH Kim, SJ Lee. 2018. Quality estimation of winter Chinese cabbage stored in purge type of controlled atmosphere storage. Food Engineering Progress. 22(1):59-66.

Lee, SG, HJ Lee, SK Kim, CS Choi, ST Park, YA Jang, KR Do. 2015. Effects of vernalization, temperature, and soil drying periods on the growth and yield of Chinese cabbage. Korean Journal of Horticultural Science and Technology. 33(6):820-828.

Lee, YJ, HO Lee, JY Kim, BS Kim. 2016. Effect of pallet-unit MAP treatment on freshness extension of spring Chinese cabbage. Journal of the Korean Society of Food Culture. 31:634-642.

Loik, ME, SA Carter, G Alers, CE Wade, D Shugar, C Corrado, D Jokerst, C Kitayama. 2017. Wavelength-selective solar photovoltaic systems: Powering greenhouses for plant growth at the food-energy-water nexus. Earth’s Future. 5:1044-1053. https://doi.org/10.1002/2016EF000531

Luo, H, H Xu, C Chu, F He, S Fang. 2020. High temperature can change root system architecture and intensify root interactions of plant seedlings. Frontiers in Plant Science. 11:160.https://doi.org/10.3389/fpls.2020.00160

Moon, HW, KM Ku. 2022. Impact of an agriphotovoltaic system on metabolites and the sensorial quality of cabbage (Brassica oleracea var capitata) and its high-temperature-extracted juice. Foods. 11(4):498.https://doi.org/10.3390/foods11040498

Moon, KH, E Song, I Son, S Oh, K Park. 2014;Simple growth model of Chinese cabbage using radiation use efficiency. In: Proceedings of the Korean Society of Agricultural and Forest Meteorology Conference; pp 134-137.

Nagashima, A 2018. Solar sharing that changes the world and the world Gyeongsan, Korea: Yeungnam University Press.

Nam, JW 2018;Agriphotovoltaic technology and structure design. In: Proceedings of PV Market Insight 2018; Daegu, Korea. pp 214.

Oh, S, KH Moon, IC Son, EY Song, YE Moon, SC Koh. 2014. Growth, photosynthesis and chlorophyll fluorescence of Chinese cabbage in response to high temperature. Korean Journal of Horticultural Science and Technology. 32(3):318-329.

Oh, W, ES Runkle, RM Warner. 2010. Timing and duration of supplemental lighting during the seedling stage influence quality and flowering in petunia and pansy. HortScience. 45(9):1332-1337.

Rural Department Administration (RDA). 2012. Research and analysis criteria Jeonju, Korea: RDA.

Rural Department Administration (RDA). 2015 July 29 After harvesting seasonal Chinese cabbage, development of storage technology and on-site distribution. RDA Press Release Retrieved from http://www.nihhs.go.kr/usr/nihhs/news_Press_list.do?pageIndex=130.

Rural Department Administration (RDA). 2021. Agricultural Technology Guidebook #128 Kimchi Cabbage Jeonju, Korea: RDA.

Seo, JH 2019;Overview of Korean PV: Market, policy and industry. In: Proceedings of PV Market Insight 2019; Daegu, Korea. pp 34.

- TOOLS

-

METRICS

-

- 2 Crossref

- 1,021 View

- 15 Download

- Related articles in J. People Plants Environ.