Identification of Factors for Active Use of Rooftop Greenhouses in Korea: Based on Analysis of Foreign Exemplary Cases

Article information

Abstract

Background and objective

There are a growing international consensus regarding the importance of achieving carbon neutrality and ensuring food security, particularly because of the “global boiling.” Rooftop greenhouses (RTGs), which reduce carbon emissions from buildings and facilitate urban agriculture, have attracted the attention of the international community as a new form of urban agriculture. Despite considerable interest in RTGs in Korea, their implementation faces limitations owing to a lack of relevant legal bases and policies.

Methods

We aimed to investigate exemplary cases to identify the essential factors for greenhouse operations and present these factors and the necessary direction for the active use of RTGs in Korea. A literature review was conducted using RTG and integrated RTG (i-RTG)-related scientific papers, books, news articles, brochures, official websites, and local government guidelines from the United States (US) and Canada where RTGs are actively used.

Results

We identified the factors required for the stable operation of RTGs in Korea: long-term support and cooperation from building owners, initial operating capital, differentiated distribution strategies, and a review of relevant laws and regulations. The latter has emerged as an important factor in identifying the legal and policy limitations associated with the operation and management of RTGs in advance. Furthermore, we discuss the need and direction for creating guidelines for RTGs to introduce and review related content. While RTGs are gaining global attention as a new form of urban agriculture, Korea lacks the relevant legal and policy bases.

Conclusion

There is a persistent need for guidelines outlining each step in the active use of RTGs at the local government level. In addition, continued discussions among the relevant experts are essential. Establishing legal and policy bases for RTGs should promote their active use, ultimately contributing to achieving carbon neutrality and promoting urban agriculture.

Introduction

We are living in the era of “global boiling,” in which the accelerated rise in temperature is changing our lifestyles (United Nations, 2023). In response to this continued rise in temperature, the international community, led by the United Nations (UN), has invested considerable effort in addressing climate change and achieving carbon neutrality. These efforts are based on agreements such as the Paris Agreement (2015) and the 2030 Agenda for Sustainable Development (Lim, 2022; Lee, 2022). Korea has also joined the international trend, setting the goal of achieving carbon neutrality by 2050 through the establishment of the Nationally Determined Contribution (NDC) and long-term low greenhouse gas emission development strategy (LEDS) roadmap (Noh, 2020).

Climate change has a significant impact on agriculture, including changes in climate zones, production environments, and food supplies (Kang, 2021). In addition, unexpected changes in domestic and international conditions and environments, including the COVID-19 pandemic, Russo-Ukrainian War, heavy rains, and heat waves, have affected the World Food Price Index and World Food Security Index, causing increased anxiety about the global food crisis (Jang et al., 2020; Lim, 2022; Lee, 2022; KREI, 2023). With the heightened importance of new agricultural methods, such as smart farming, for resolving these food security issues, the research and development of modern technologies is being undertaken in various fields (Kim and Yoe, 2022). Smart farms have gained attention as state-of-the-art agricultural methods that utilize novel technologies to enhance crop growth. They enable year-round cultivation regardless of external factors, such as season and weather, while facilitating real-time monitoring (Yeo et al., 2016; Han and Joo, 2022). Recognizing their potential, South Korea has made significant efforts to promote the active use of smart farms.

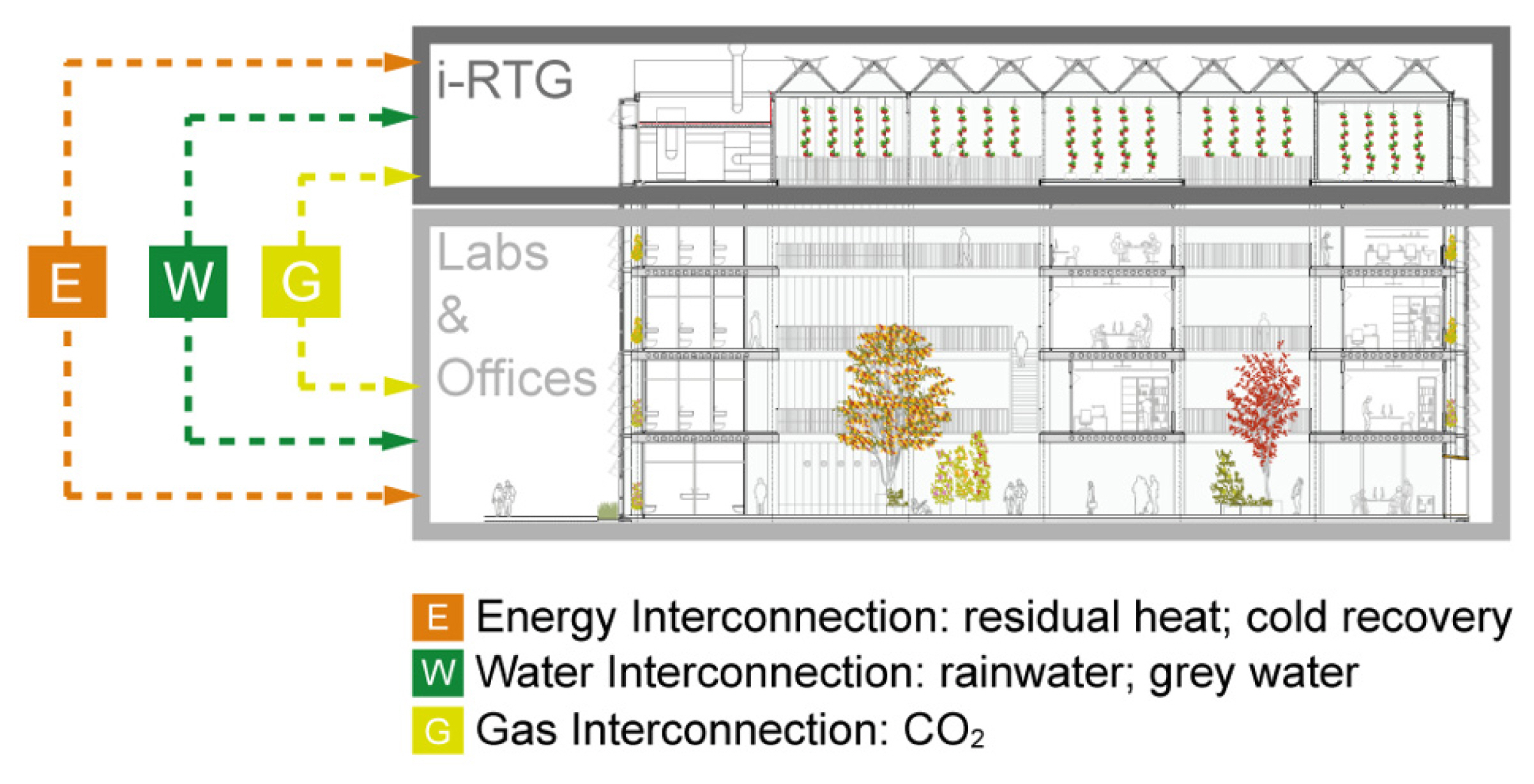

Upon examining exemplary cases of active smart farm use, we discovered a unique type of rooftop greenhouse (RTG) smart farms which are integrated with buildings. These integrated-rooftop greenhouses (i-RTGs) have been employed in various countries (Sanjuan-Delas et al., 2017; Montero et al., 2017). According to Appolloni et al. (2021), most i-RTGs with available data as of 2021 are located in North America (41.4%) and Europe (34.5%). RTG-type smart farms are a form of urban agriculture in which crop production occurs within greenhouses installed on building rooftops, thereby improving the building energy efficiency (Nadal et al., 2017; Specht and Sanye-Mengual, 2017; Nadal et al., 2018). Greenhouses use waste heat and carbon dioxide generated inside buildings to create a crop-growth environment (Ercilla-Montserrat et al., 2017; Benis et al., 2017). Moreover, since RTG-type smart farms are not affected by external climates such as seasons and wind, they offer the advantage of creating additional income from crops harvested and sold year-round. Accordingly, RTG-type smart farms are used in commercial greenhouses. This method of farming is characterized as being eco-friendly, employing hydroponics for crop cultivation, and imposing a lighter load burden than regular smart farms. This quality makes it suitable for installation on building rooftops in urban areas, warranting recognition as a novel form of urban agriculture (Nadal et al., 2017; Choi 2021a). RTG-type smart farms also offer the synergistic effect of promoting the active use of urban agriculture and improving energy efficiency by reducing building energy consumption and using energy discarded from buildings to grow greenhouse crops (Lee and Choi, 2022) (Fig. 1).

Korea is also establishing policies that recognize the importance of advanced agriculture and smart-farm implementation. According to the New Growth 4.0 Strategy Promotion Plan announced in February 2023, the central government is pursuing the enactment of the “Smart Agriculture and Fishery Act” and preparing strategies for establishing urban complex vertical farms (Government of The Republic of Korea, 2023). At the local government level, Daejeon is pursuing the establishment of smart farms and activation projects using spaces within abandoned buildings in downtown areas (Business and Employment Agency of Daejeon, 2023). Moreover, private companies, including construction companies, recognize the potential of smart farms and invest in R&D. Notable companies such as Lotte Engineering and Construction, along with Daewoo Engineering and Construction, are actively engaged in the development of smart farm technologies that can reuse carbon dioxide generated by hydrogen fuel cells in buildings (Hyun, 2023). The integration of smart farms within buildings is gaining attention in various fields.

RTG-type smart farms have already been installed in Korea, including the Korea Institute of Machinery and Materials (KIMM) WISE Farm (Lee et al., 2020; Lee and Choi, 2022), Daedong Smart Farm (Daedong, 2023), and the Korea Institute of Science and Technology (KIST) Smart U-Farm (Kim, 2015). However, they are only used for internal research purposes and are not accessible to the public. Moreover, the implementation of RTG-type smart farms in Korea faces various challenges due to a lack of relevant laws and policy bases. Regarding current research trends, multiple studies have explored numerous topics related to smart farms, including greenhouse crop selection and cultivation methods (Cho et al., 2022), control systems (Kim et al., 2018; Choi, 2021b), policy processes (Kim, 2021), and the interpretation of energy flow (Kim et al., 2019; Choi et al., 2020). However, almost no case studies have focused on smart farm operation models, and those related to RTG-type smart farms are scarce.

Despite the constant attention gained by RTG-type smart farms for their efficiency and convenience, they remain in the R&D stage due to the absence of relevant legal and policy bases. Furthermore, the operational aspects of RTG-type smart farms have not been studied as extensively as their developmental aspects. Accordingly, we aim to investigate exemplary cases of RTG-type smart farm operations to identify the requisite factors, and provide guidance for the successful implementation of RTG-type smart farms in Korea.

Research Methods

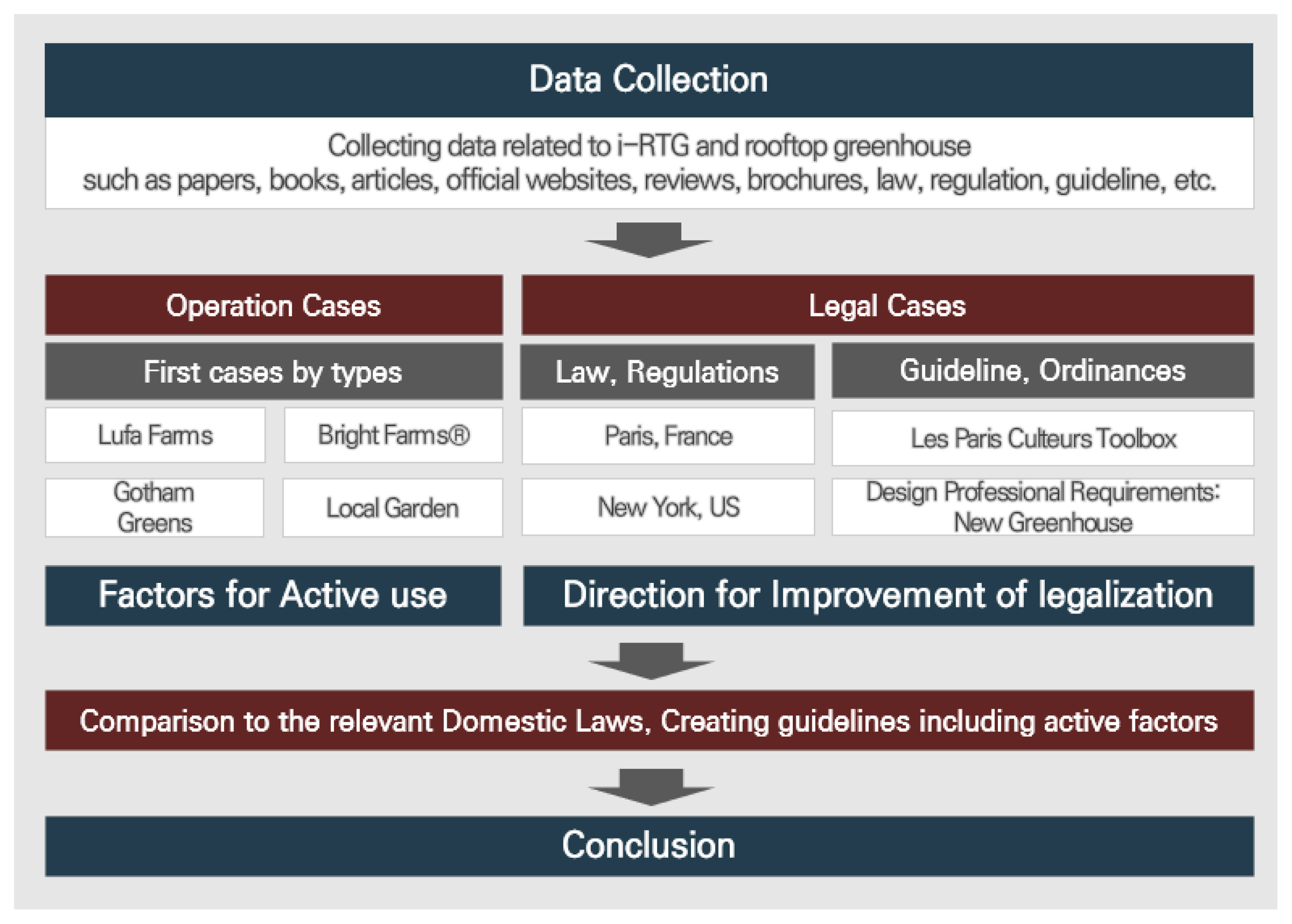

In Korea, there a re no installed RTGs available to the general public, and no RTG-related legal and policy bases have been established. Accordingly, we conducted a literature review of the RTG operational factors and policy bases in exemplary cases of RTG implementation to identify the essential factors required to facilitate the implementation and promotion of RTG-type smart farms in South Korea. For this purpose, we selected i-RTGs and RTGs situated atop buildings that are commercially used outside of Korea as data sources (Fig. 2).

The research methods were as follows: we collected literature related to RTG and i-RTG published by credible institutions or sources with clear identifications, including scientific papers, books, news articles, official websites, brochures, and guidelines from outside of Korea. Subsequently, we analyzed the collected data and categorized them into operational and policy cases. The operational factors collected included aspects of general operations, such as establishment processes, operating capital, income generation, and sales/distribution strategies. The policy factors collected included guidelines issued by public or governmental institutions.

After analyzing the collected data, we chose the companies Lufa Farms and Local Garden in Canada and Gotham Greens and BrightFarms® in the United States (US), which are still growing or have received international attention in the past, as operation cases. These companies, either still in a growth phase or having received international attention in the past, offer valuable insights. Additionally, we selected the Les Parisculteurs Program of France and the “Design Professional Requirements: New Greenhouse” of the US as policy cases. These programs have relevant guidelines for public access with specific policy/administrative procedures, including those for the installation and approval of RTGs.

Results

Operation cases

Lufa Farms, Canada

Lufa Farms, Canada, is the world’s first commercial and largest urban RTG (Korea Trade-Investment Promotion Agency, 2021; TYM, 2022). In 2006, plant scientists, agricultural specialists, engineers, and architects launched the first Lufa farm. Over the following four years, Lufa Farms focused on developing hydroponic-based irrigation, solar-powered cultivation, pest control and management systems, and software based on these technologies for ecofriendly greenhouse operations. Presently, in collaboration with McGill University, Lufa Farms continues its research aimed at creating an optimal growth environment for each type of crop, considering the changing environments and conditions (Proksch, 2017). Their first greenhouse, 3,000 m2 in size, was installed in their office building in 2009. Since then, through subsequent expansions in 2013, 2017, and 2020, Lufa Farms acquired four RTGs. Starting with the first harvest from the initial greenhouse in April 2011, Lufa Farms produced 122 tons per acre of over 100 varieties of vegetables and herbs each year, which was sufficient to feed more than 20,000 residents throughout the week (Fig. 3).

Montreal Lufa farms, the world’s largest rooftop greenhouse (L); Lufa farms produced crops and community-supported agriculture crops (R).

*Source: (L) Agritecture webpage (agritecture.com); (R) Montrealmom (2014)

To establish the foundation of the company, including the installation of a greenhouse and technology development, as well as securing the funding required to cover early-stage operational costs, Lufa Farms devised and promoted a comprehensive business plan. This plan outlined the installation and operation of a rooftop smart farm, incorporating agricultural expertise, innovative ideas, and the strategic direction of greenhouse operation. The objective was to attract external collaboration and support for the successful launch of the company. To secure the space where the greenhouse would be installed, which is the most important aspect of the endeavor, Lufa Farms engaged in long-term agreements with a real estate investment trust company responsible for several commercial properties in the Montreal area, which ensured the stability of the company’s post-installation operation. In addition, farms adopted a community-supported agriculture (CSA) distribution system, where consumers and Lufa Farms jointly operated the RTG to secure the funds needed for the initial operation (Proksch, 2017). CSA is a distribution system that moves away from the traditional system of producers being responsible only for production and consumers only purchasing products; instead, it is a bidirectional system in which consumer participation starts from the production process. Lufa Farms set up pick-up points at cafés, bakeries, and cultural centers in areas without nearby grocery stores and delivered seasonal eco-friendly crops produced in RTGs to those points for 12 weeks using electric vehicles (KOTRA, 2021; Lufa Farms, 2023). In addition, Lufa Farms operates an online shopping mall for direct-to-consumer sales to get closer to consumers. According to Proksch (2017), the company generated USD 1.2 million in income in its first year of operation and secured US$4.5 million in equity investments from a venture capital fund. Lufa Farms recouped its initial capital within the first 18 months of operation by recruiting consumers who could support the distribution and sales of products and private investors who could invest in the installation and operation of the RTG without any public support, such as subsidies (Proksch, 2017).

The CSA distribution system was the largest contributor to the growth of Lufa Farms. To maximize production satisfaction among consumers, Lufa Farms strategically partnered with local farms, fostering collaborative growth (Fig. 4). Consumers choose to purchase seasonal crops grown exclusively on Lupa Farms and seasonal crops supplied by local farms. This sales method offers advantages for both Lufa Farms and local farms to grow together while granting consumers direct access to various seasonal products, including those cultivated by Lufa Farms. This distribution strategy, which allowed consumers to conveniently purchase crops cultivated using eco-friendly methods, gained attention from the community and became the foundation for the growth of Lufa Farms.

Gotham Greens, the US

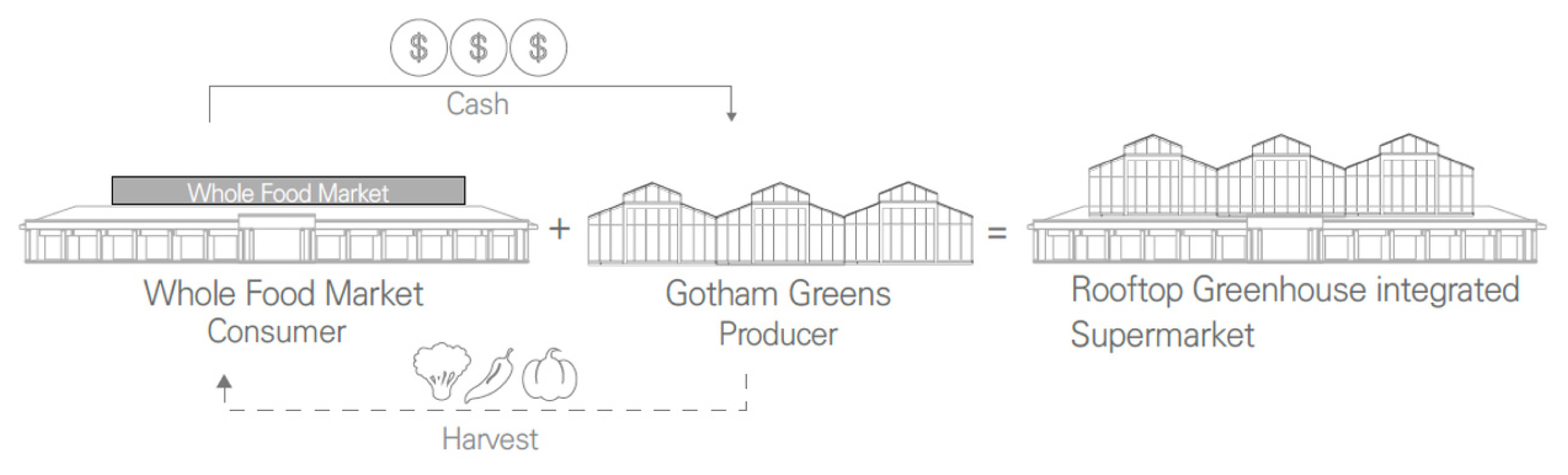

Gotham Greens is the largest commercial RTG in the US, and is considered an excellent case for establishing a distribution system with a major supermarket. In 2009, a team including start-up support, greenhouse, and financial experts founded Gotham Greens, and the first commercial RTG was installed in Brooklyn, New York, in 2011. Greens attempted a new form of RTG-type urban agriculture by installing greenhouses on the rooftops of vacant buildings in urban centers to reduce costs, shorten the time associated with long-distance distribution between urban and suburban producers, and maintain the freshness of agricultural products.

In 2011, Gotham Greens has its first harvest. The company developed and installed a prototype greenhouse, which was approximately 1,395 m2 in size and capable of producing approximately 45.36 tons worth of crops per year by hydroponics. However, the productivity per unit area was lower than that of indoor vertical farm specialists, such as Aero Farms or Plenty (Ryu, 2020). Although Gotham Greens achieved its goal of short-distance distribution, it still required its own urban distribution network. In 2013, Gotham Greens signed a 20-year long-term agreement with Whole Foods Market (WFM), an eco-friendly supermarket chain, and installed its second greenhouse, its first supermarket-integrated RTG (Hansalim, 2017) (Fig. 5).

The philosophy of the WFM and the operating goals of Gotham Greens, including eco-friendly crop cultivation, short-distance distribution, and delivery within 18 miles, were integrated into RTG (Stevens, 2013; Media SR, 2013). After signing the agreement with WFM in 2013, Gotham Greens received an outside investment of USD 750,000, and in the following year, it received a “Best” rating from the 2014 Whole Foods Market Responsibly Grown Rating System. In 2015, Gotham Greens installed its third greenhouse after receiving a subsidy of USD 900,000 from New York State Department of Economic Development. In January 2018, Gotham Greens again proved its value by securing an investment of USD 29 million (Ryu, 2020). Currently, Gotham Greens has 11 RTGs and continues to expand its business (Gotham Greens). According to Proksch (2017), Gotham Greens produced 400 tons per acre of crops annually as of 2017 and has continued to scale up production since then, following the installation of their eight greenhouses.

Because crops from Gotham Greens are cultivated using hydroponics, they do not qualify for the organic certification provided by the US Department of Agriculture (USDA) for crops cultivated on American soil (Hansalim, 2017). Nonetheless, eco-friendliness and food safety have been ensured through long-term agreements with the WFM, which sells only eco-friendly products. Consequently, the WFM recognizes crops cultivated by Gotham Greens using rooftops in urban spaces as eco-friendly crops, based on how they are produced and distributed (Fig. 6). These criteria include the use of renewable energy, such as solar and wind energy; cultivation by hydroponics; minimal water consumption (only 1/10 of the water required for open field farming); and the distribution of crops within 24 h after harvesting (Zeveloff, 2011; Proksch, 2017; Ryu, 2020).

Gotham Greens, which installed a greenhouse on the rooftop of a whole foods market (L); Product development by whole foods market and Gotham greens

*Source: (L) Nguyen (2022); (R) Gotham Greens (2021)

BrightFarms®, US

BrightFarms® of the US originated from New York Sun Works (NYSW), a non-profit organization that supports sustainable urban agriculture, and grew to become a consulting firm specializing in greenhouses. NYSW, which installed RTGs on the rooftops of urban schools as laboratories, was founded in 2004 to support experiments and education on sustainability in which students and teachers can participate (Kay-Twelve, 2023). In 2007, NYSW developed the Science Barge, a prototype urban greenhouse that grows eco-friendly crops using solar energy and rainwater on a steel deck barge floating on the Hudson River in Manhattan, and provides a venue for sustainability education for students and local residents (Groundwork, 2023) (Fig. 7). Based on its experience in developing and installing greenhouses, NYSW established Bright Farm Systems in 2008 as a consulting company that provides RTG-based agricultural technology services. In 2011, Bright Farm Systems merged with Better Food Solutions, a company specializing in hydroponics, to form a new urban greenhouse consulting firm called BrightFarms (Gibson 2014; Signature Exteriors 2017).

Science Barge, the prototype from BrightFarmsR (L); commercialization of crops produced by BrightFarmsR (R)

Sources: (L) Trangle (2012); (R) Sowder (2021)

In 2011, BrightFarms installed the world’s largest hydroponic greenhouse, approximately 100,000 m2 in size, on the rooftop of the Brooklyn Navy Yard, constructed in 1916. This greenhouse can grow enough tomatoes, lettuce, and herbs to feed 5,000 people annually (Fleetowner, 2012). During this period, when the average cost of installing a greenhouse was USD 1.5–2 million (Scharwath, 2012), BrightFarms® strategically entered into long-term agreements with 10 US grocery and supermarket companies, including the Great Atlantic and Pacific Tea Company, Inc. (A&P) and Mcffery’s Market, to secure financing for greenhouse installation and operation. McFerrty’s Market, which has stores in Pennsylvania and New Jersey, was the first grocery company to sign a produce purchase agreement (PPA) with BrightFarms. The BrightFarms® PPA is an agreement by which the purchaser or reseller agrees to acquire crops at set prices; the PPA is similar to the power purchase agreement used in the solar energy industry (Gibson 2014) (Fig. 8). A&P became the third grocery company to sign a PPA using BrightFarms (Business wire, 2012). Crops produced by BrightFarms using hydroponic farming boast an extender shelf life, maintaining optimal freshness for a long time and this minimizing spoilage until delivery to consumers. After being recognized by the community for this benefit, BrightFarms® initiated its venture with an investment of USD 4.3 million in December 2011 and expanded the market share by continuing to install additional greenhouses using grants and subsidies from the community, non-profit organizations, and development agencies (Scharwath, 2012). In 2018, the company secured a substantial investment of USD 55 million from companies in diverse industries unrelated to greenhouses, including the telecommunications, media, and automotive service industries (Cosgrove, 2018).

However, securing rooftop spaces and capital for greenhouse installation, which is required to strengthen its distribution system and expand its business, poses a challenge (Ferris, 2012). The RTG business, which began with the goal of replacing local specialty products from distant places, shifted into a distribution strategy exclusive to BrightFarms® through long-term agreements with grocery and supermarket companies (Manning and Burwood-Taylor, 2016). Accordingly, BrightFarms® began installing greenhouses on ground space instead of rooftop spaces to minimize greenhouse installation, operation, and management costs and to make it easier to provide crops to the contracted companies (Gibson 2014). This spatial change in greenhouse placement offered significant advantages to BrightFarms® of being able to save greenhouse installation, operation, and management costs and the contracted partners to supply the harvested crops to the consumers within a short time (Scharwath, 2012). As of 2022, BrightFarms® continues to grow with an average annual revenue of USD 11.5 million (ZIPPIA, 2023).

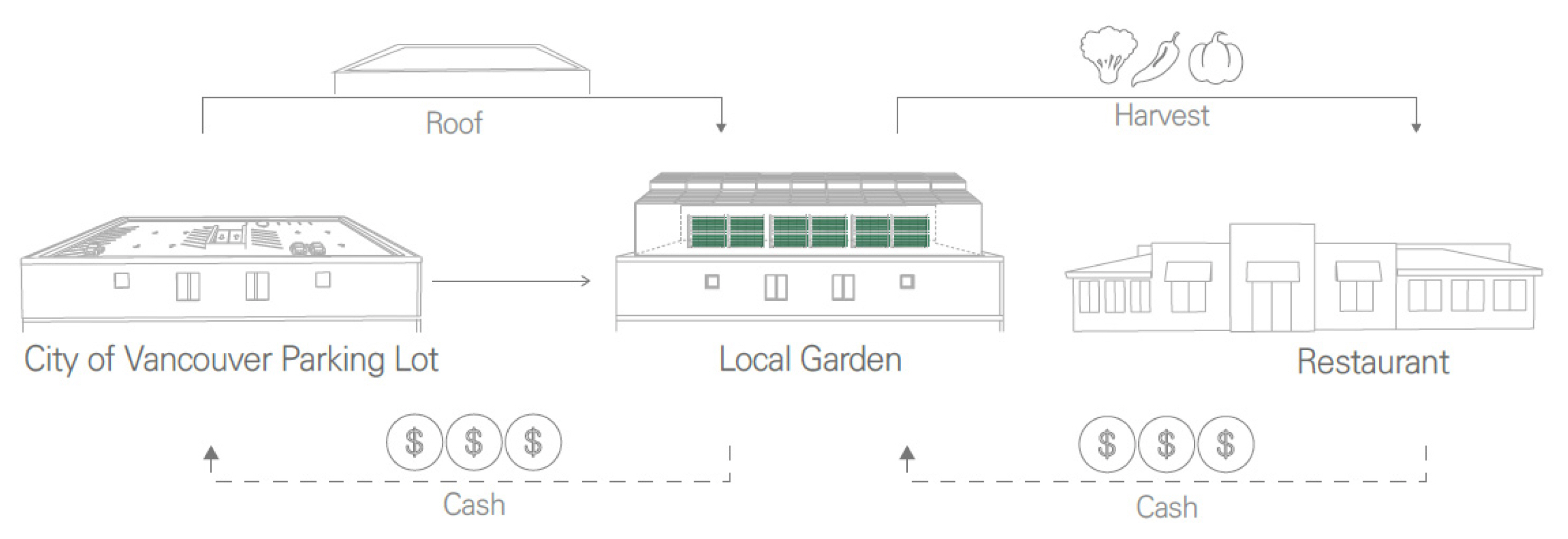

Local Garden, Canada

The Local Garden, which was the first in Vancouver, Canada to develop and operate a commercial vertical farm (Fong, 2012), is a prime example of an RTG installation with a public partnership; however, it is also known as a failed operation case. Valcent, a British company founded in 1996, developed an eco-friendly vertical cultivation system. In 2008, Valcent developed VertiCrop, a vertical cultivation system that can grow crops by stacking 12 trays vertically (DH, 2017). Due to the economic recession at the time, the company relocated from the United Kingdom to Canada and changed its name to Alterrus System Inc. For the stable operation and management of greenhouses, in 2012, Alterrus established a wholly owned subsidiary called Local Garden Vancouver Inc. (Crawford, 2012) and became the first in North America to install an RTG of 560 m2 on the rooftop of a parking garage building owned by the City of Vancouver (Ng, 2013) (Fig. 9). The Local Garden signed a 10-year lease agreement for a low monthly rent of CAD 2,400 with Vancouver, which owns the right to use the parking garage rooftop, enabling it to secure the space needed to grow its crops and stably promote VertiCrop as its proprietary system (Hutchinson, 2014). Vancouver made the rooftop space available to local gardens based on the expectation that renting the rooftop space would generate more revenue than using it as a parking lot (Proksch, 2017) (Fig. 10).

Local Garden (L) / VertiCrop vertical cultivation system (R).

*Sources: (L) Perutka (2019); (R) Wolak (2012)

The Local Garden was expected to produce 75 tons per year through vertical hydroponic farming; however, it supplied products to only 12 grocery stores and restaurants in downtown Vancouver, aiming to maintain freshness and minimize nutrient loss from harvested crops (Wolak, 2012; Perutka, 2013). In the first semester of 2013, the first year after construction was completed, the Local Garden generated approximately CAD 320,000 in sales, but also suffered losses of over 1 million in losses due to greenhouse energy supply issues (Hutchinson, 2014). Owing to Vancouver’s restrictions on solar panel installation, highly stacked cultivation trays require a significant amount of supplemental lighting.

Consequently, the production of broadleaf crops has become difficult and production has shifted to microgreens and pesticide-free vegetables that can be grown at higher profit margins and lower operating costs (Levenston, 2014; DH, 2017; Proksch, 2017). However, the company faced difficulties finding distribution channels because the products did not meet local demand. By the end of December 2013, greenhouse operations were suspended owing to equipment malfunction inside the greenhouse, which limited crop cultivation and delivery. Consequently, the company was unable to overcome its financial difficulties, which included over CAD 4 million in debt (Shore, 2014; Greer and Denis, 2015). In January 2014, the parent company, Alterrus Systems Inc., and its subsidiary, Local Garden Inc., went bankrupt (Shore, 2014; Proksch, 2017).

Operational Strategies of 4 exemplary cases

The primary aim of the four greenhouses is to reduce food mileage by minimizing packaging, storage, and transportation between consumers and producers, and delivering fresh produce directly to the local community within a short timeframe. Strategically located in close proximity to large cities, these greenhouses specialize in exclusively selling locally harvested crops. It is noteworthy that each company applies its own eco-friendly technologies to operate greenhouses for cultivation; however, overall, they are based on hydroponic cultivation techniques. Most food companies utilize otherwise unused rooftops as fields and rely on renewable energy sources such as sunlight, water, and wind for basic greenhouse operations. Hydroponic cultivation requires less water than open-field greenhouse operations, making it economically viable. However, owing to limitations in hydroponic cultivation technology and securing deep soil necessary for crop growth, the cultivated crops typically include vegetables and herbs, such as tomatoes, basil, lettuce, cucumbers, and bell peppers.

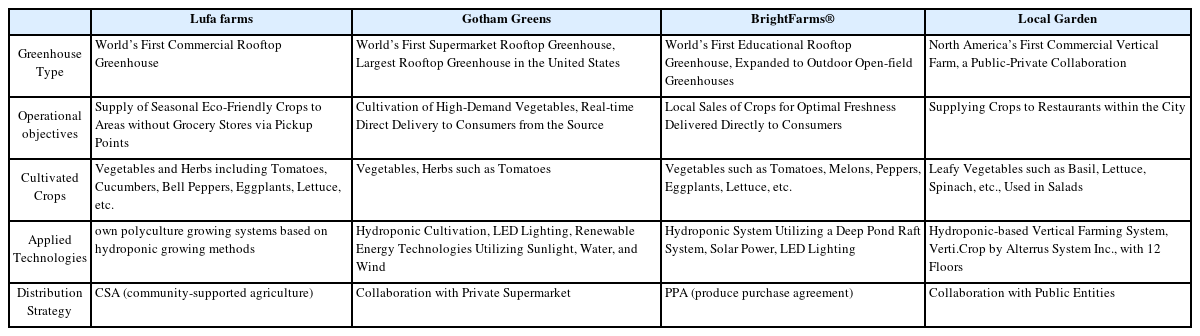

Each company operates a greenhouse using a differentiated operational model that reflects its vision and conditions. Some collaborate with private supermarkets to distribute organic crops over an extended period, whereas others enter fixed-price contracts for crop distribution (Table 1). Additionally, there are cases in which companies collaborate with local farms to operate and supply seasonal crops to consumers at the desired time. Some companies lease the rooftops of abandoned buildings owned by the city at affordable prices for long periods to operate greenhouses. However, considering cases of rapid growth, bankruptcy, or the development of community education, it is evident that the degree of company growth varies based on the operational model and economic and external factors.

Legal cases

Law and Regulations Cases

Paris city, France

In 2016, the city of Paris, France, revised its urban planning regulations to promote the greening of urban buildings and encourage urban agriculture. The revision included additional provisions for agricultural greenhouses, allowing exceptions to the previously strict height regulations for Parisian buildings, specifically for agricultural production and renewable energy facilities. According to the Paris City Urban Planning Regulation UG 10.1, structures designed to save energy and produce renewable and recyclable energy, such as solar heating and green roofs, can exceed height restrictions. This regulation explicitly includes agricultural production facilities and greenhouses installed on rooftops. Moreover, if these facilities are adjacent to roads or property boundaries, a protrusion up to 0.2 m is permitted (Mairie De Paris, 2016). In other words, rooftop greenhouses, as agricultural production facilities installed on rooftops, qualify for an exception clause under the Paris City Urban Planning Regulations. An illustrative case involves the construction of a 20 m-high rooftop greenhouse on top of the Tour Montparnasse Tower, which faced legal challenges from citizen groups. However, the court recognized it as an agricultural production facility under UR 10.1, eligible for official approval because of its potential to enhance the building’s energy performance (Leparis, 2021).

Despite the existence of regulation (R412-9-12) outlining procedures for declaration and permit issuance, including aspects such as prior notification, declaration scope, permit duration, and demolition orders, specific criteria for rooftop greenhouse installations remain undefined. Determining details such as dimensions, height, materials, and equipment poses a challenge. For greenhouses exceeding a height of 4 m and a floor area of 2,000 m2 or more above the ground, approval from the local authorities (i.e., the mayor) is mandatory, with a permit duration of three years (Jardincouvert, 2023).

In summary, Paris currently lacks specific standards for rooftop greenhouse installations, and regulations are treated as exception clauses. The Mayor, serving as the permitting authority, has discretionary power over rooftop greenhouse installations. Given these circumstances, Paris may encourage rooftop greenhouse gas activation by employing exception clauses instead of stringent regulations. The Mayor may recognize rooftop greenhouses as urban agriculture facilities, provided that structural safety concerns and other serious issues are adequately addressed.

New York city, US

In response to social demands to alleviate the urban island heat effect and reduce the greenhouse gas emissions, New York City enacted ‘Local Law 22 of 2008,’ which included provisions for rooftop agriculture. Subsequent amendments in 2011, expanded regulations to explicitly permit the planting of vegetation and installation of greenhouses on rooftop spaces (NYC Council Legislation). The enactment of Local Law 49 of the same year marked a comprehensive update to administrative and building codes, specifically pertaining to the construction and operation of greenhouse. According to Building Code (BC) 504.3, rooftop greenhouses are explicitly excluded from the total height of the building, provided they fall within a range that does not exceed 33.3% of the building’s roof area, and they are not recognized as extension acts (NYC AD Code, 2023). An exemption is granted for environmentally friendly facilities such as solar panels, even if they surpass the 33% limit, they are not considered extension acts. Building Code BC 1509.7 provides detailed specifications for rooftop greenhouse materials, specifying the use of non-combustible materials, ordinary or wire glass, and light-transmitting materials, following the regulations for light-transmitting plastic materials in Section 2606 and fire-resistant structure codes in Table 604 (NYC Code; MY, 2014).

Furthermore, in accordance with the local laws, the administrative and building codes of New York City, the Zoning Resolution (ZR) 75-01 were amended to regulate aspects related to rooftop greenhouses, including height, floor area ratio calculations, and certification (NYC Planning, 2014). Notably, agricultural rooftop greenhouses are recognized as permitted obstructions, allowing for their installation with a maximum height of 25 feet and a transparency of over 70% in all zones where agricultural use is permitted within the city (NYC, 2014). During the amendment process, the City Planning Commission conducted public hearings to collect input from local residents.

Unlike Paris, New York City’s zoning law explicitly outlines criteria for rooftop greenhouse installation, including standards for area, height, and accessory building area. While the permitting authority for rooftop greenhouse installation lies with the local authorities, the approval of the City Planning Commissioner is required for criteria and exceptions related to rooftop greenhouse area and height.

Guideline cases

The Parisculteurs toolbox, France

Paris, France, produced and distributed a manual called the “Parisculteurs Toolbox, which describes the overall content of the Les Parisculteurs program (Ville De Paris, 2020). Les Parisculteurs is a partnership program between Paris and private companies that promotes urban roof greening and agriculture. Participating companies provide available rooftop spaces, and Paris oversees the programme’s operation while disclosing its contents, procedures, and status through its website (Les Parisculteurs). Interested parties can apply for the program by preparing a business plan and referring to a toolbox that contains general information about the program, including the technical and regulatory frameworks that need to be reviewed at each stage. The toolbox introduces RTG as a type of urban agriculture and specifies general matters related to RTGs, including standard specifications, fixation methods, installation materials, joint sealing, conditions for the internal climate and growth environment, food safety regulations, and the relevant legal framework. In addition, it introduced various types of distribution strategies and business models to reduce the burden on applicants writing business plans for the first time.

Design professional requirements: New greenhouse, New York city

In the US, New York City (NYC) developed a set of checklist-type guidelines known as “Design Professional Requirements: New Greenhouse.” These guidelines are intended for use by RTG designers, builders, and building owners and are readily accessible on the NYC Department webpage. The guidelines introduce in detail the installation standards that vary according to the location of the RTG, as well as relevant regulations, including zoning, building, and construction codes. Additionally, they provide guidance on business plan writing and permit application processes. Furthermore, the guidelines describe the steps that building owners must follow to obtain permits for RTGs outside the general administrative process, including public design certification, Landmark Preservation Commission review, submission of special inspection findings, and assignment of onsite safety managers. The permit for RTG was reviewed and approved by the City Planning Commission. The guidelines specify the roles of designers, builders, and building owners, which reduces the burden of administrative procedures and relevant regulatory reviews for building owners installing greenhouses for the first time.

Comparison between New York City, US and Paris, France

In the second section on legal cases, we conducted research and analysis on legislative and regulatory cases in New York City in the United States and Paris in France (Table 2). Both local governments have garnered attention as advanced cases influencing the establishment and revision of relevant laws at the local government level. In addition, they have played a significant role in the development of guidelines facilitating the smooth installation of rooftop greenhouses.

The revision of laws related to rooftop greenhouses in these regions originated from the need to address urban environmental issues, such as mitigating the urban heat island effect through greenhouse gas reduction. Rooftops of buildings, often considered unused spaces within the city, have been identified by citizens as high-potential areas for both greenhouse gas reduction and urban agriculture. Through local-government-led legislative revisions, related regulations and ordinances were amended, and the corresponding standards, guidelines, and regulations for rooftop greenhouse installations were drafted and distributed. New York City established specific criteria for rooftop greenhouse installations, whereas Paris explicitly designated rooftop greenhouses as an exception to its regulations.

Discussion

Active use factors of rooftop greenhouse in Republic of Korea

This study analyzes exemplary cases of RTG operations and policies implemented outside Korea. Based on our findings, the following commonalities were identified: each RTG created an optimal cultivation environment for crops through the development of its own technologies, including hydroponic and vertical farming technologies; specialized distribution strategies were established through long-term agreements with supermarkets and grocers, CSA, and PPA that reflect consumers’ demand; local governments and public institutions produced and distributed the checklists or guidelines required for the greenhouse installation process; and the guidelines prepared by the public organs provided clear instructions on RTG installation for building owners, greenhouse users, and builders while also presenting directions for completing complicated administrative procedures. Based on an analysis of exemplary cases, the operational factors and policy support needed for the implementation of RTG in Korea include the following:

Support and cooperation from building owners: To secure spaces for RTGs, it is necessary to obtain the consent of building owners who hold authority over the operation and management of buildings. The early success of companies such as Lufa Farms and Gotham Greens, which continued to grow in their early stages of activities, can be attributed to the cooperation of private building owners, including real estate and supermarket companies, who actively facilitated greenhouse installation on the rooftops of buildings. Moreover, when building owners were public entities or local governments, rooftop spaces were secured at relatively low prices, as in the case of local gardens.

Initial capital requirement: Operating the RTG after installation requires initial capital. While financial support, such as grants and subsidies, can be obtained through local public projects or local government policies, reserve funds are also required for the repair and maintenance of greenhouse-related machinery and infrastructure. For instance, Lufa Farms and Gotham Greens have entered into distribution agreements, enabling them to secure essential funding. Alternatively, external investments can be sought by promoting proprietary technologies developed in-house. Lufa Farms has developed its own vertical cultivation technology and related software over the four years since its foundation and prepared a business plan based on its in-house technology to secure investment in operating capital. BrightFarms® also gained recognition from the community through the Science Barge on the Hudson River, which was developed based on an eco-friendly crop cultivation system developed in-house. Local Garden also promoted its own vertical hydroponic system, VertiCrop.

Differentiated distribution strategies for continuous and stable income: The strategies found in the exemplary cases consisted of distributing only to the community, since the primary goal was to maintain the optimal freshness of the produced crops. Lufa Farms’ CSA strategy has attracted the attention of consumers as a structure that promotes growth through coexistence with local farms. Gotham Greens partnered with the Whole Foods Market to become the first to install a supermarket-integrated RTG to distribute harvested crops directly to supermarkets. BrightFarms® secured its distribution channel through a PPA with grocery and supermarket companies, allowing for the distribution of crops at set prices for a long time. Local Garden has also established a distribution structure with only 12 grocery stores and supermarkets in the local community of downtown Vancouver.

Reviewing relevant laws and policies before planning RTG installation: Depending on the relevant local laws, construction of the planned RTG may not be allowed because of architectural and landscape regulations such as height restrictions, exterior material restrictions, and light pollution. Local Garden of Canada faced a setback with internal energy supply for greenhouses due to Vancouver’s height restriction on solar panel installation and was forced to spend excessive operating costs on the unexpectedly high use of supplemental lighting. This caused delays in crop production and degradation of product quality, resulting in a failure to abide by the agreement with distributors and led to a loss of trust in Local Garden within the community. This case demonstrates the importance of checking relevant laws and policies in advance.

The direction of legal and policy establishment for the active use of roof rooftop greenhouse in Republic of Korea

Presently in Korea, there is no legal basis for explaining the RTG standards, installation, operation, and administrative procedures despite the existence of various guidelines based on the relevant laws and applicable provisions, such as the “Building Act” and “Act on Development and Support of Urban Agriculture.” The installation of structures on rooftop spaces for agricultural and fishery-fixed greenhouses must be reported and permitted in accordance with Article 15, Paragraph 5, and Clause 11 of the Enforcement Decree of the Building Act. Article 8 of the Urban Agriculture Act defines the types of urban agriculture, and rooftop greenhouses align spatially with urban-type urban agriculture, as specified in Clause 3 of Paragraph 1. However, provisions regarding the installation of structures such as greenhouses are lacking, and according to the Act on Development and Support of Urban Agriculture, individuals other than agricultural stakeholders cannot generate income by selling produced crops. The Smart Agricultural and Fishery Act, aimed at enactment in ‘23 (temporary act title), which regulates smart farming technologies applicable to rooftop greenhouses, has not yet been enforced. Recently enacted laws, such as the Carbon Neutrality Framework Act for Coping with Climate Crisis and the Climate Change Response Technology Development Promotion Act, identify rooftop greenhouses as part of green technology and climate change response technology. However, they stipulate the requirement of separate certifications. Similar to other technology-related regulations, the Green Buildings Construction Support Act classifies rooftop greenhouses as a technology for improving building energy efficiency, necessitating a separate certification. While the Carbon Neutrality Act, which comprehensively covers all sectors and is capable of linkage, could be considered a basis for rooftop greenhouses, the lack of completed enforcement decrees and regulations makes it challenging to connect with provisions related to rooftop greenhouses (Korean Law Information Center-webpage).

Various support programs such as financial support and regulatory relief are essential for the smooth promotion and activation of rooftop greenhouses in South Korea. Although incentive clauses exist for G-SEED (Green Standard for Energy & Environmental Design) and ZEB (Zero Energy Building) certification under the Green Buildings Construction Support Act, rooftop greenhouses are not specified in the certification or evaluation criteria. As the G-SEED-related provisions are currently under revision, it is necessary to assess whether post-revision linkage is possible (KLIC webpage).

Meanwhile, numerous laws and regulations, including allowable load, fire safety requirements, natural disaster prevention requirements (including earthquakes), floor area ratio, building coverage rate by land use, and height restrictions applicable to buildings, must be reviewed when installing greenhouses. However, it is difficult for building owners to thoroughly review the legal regulations applicable to buildings in which greenhouses are to be installed. This complicated legal and administrative procedure may be a major reason building owners discard the idea of installing RTGs. Therefore, to implement RTGs in Korea, standard guidelines must be developed at the government level to provide directions for RTG installation and operation at each stage, including greenhouse installation standards, operating plans, and management systems. While various legal regulations are applicable to building rooftop structures and installations, the head of local government has authority over the approval and permit process; thus, it is necessary to reflect the ordinances and relevant matters governed by the head of local government in the guidelines. Paris and NYC York promote active participation by building owners and RTG operators by preparing and distributing guidelines on RTG installation at the local government level. Therefore, if local government-level guidelines that introduce regulations and reflect the local environment and conditions are developed based on the directions suggested in the central government’s guidelines, they can support local governments’ efforts to implement RTGs.

Conclusion

With the acceleration of climate crisis, food security has rapidly emerged as a global agenda, along with the realization of carbon neutrality. In the international community, i-RTGs have gained attention as an option for the implementation and active use of urban agriculture as well as the reduction in carbon emissions in the building sector. Continuing with this trend, countries outside of Korea, including the US, Canada, and France, have designated RTG as a new form of urban agriculture and are actively supporting the installation of RTGs through the establishment of relevant legal and policy bases.

This study investigated exemplary foreign cases to identify the factors required for operating each RTG and the policy support provided for the active use of RTGs at the public level. In addition, this study discusses the factors required for the active use of RTGs, including planning, operation, management, and policy support, considering the environment and conditions of Korea. In particular, for the commercialization of RTGs introduced in Korea for research purposes, the study also emphasizes the need to prepare guidelines at the central and local government levels to promote active participation by building owners and greenhouse operators. Regarding the content of the guidelines, continued discussions among various stakeholders including public officials, researchers, and experts from various fields are required. The preparation of such guidelines can help address a gap in the legal and policy bases for RTGs in Korea. The initiatives positions RTGs as a novel form of urban agriculture, particularly in this era of “global boiling”. Establishing RTGs as a recognized aspect of urban agriculture which can contribute to a future where carbon neutrality and response to food security issues may be achieved.

This study is constrained by the limited examination of legal and policy matters regarding various greenhouse cases. In particular, as each local government may have different ordinances and guidelines, a more extensive review of cases is crucial. Consequently, a more detailed analysis of laws and policies, including relevant ordinances and guidelines that support the active use of RTGs, should be conducted in future studies.